2023 Highlights of UHPC Developments in China

UHPC Branch-association of China Concrete & Cement-based Product Association (CCPA)

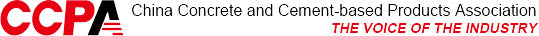

Volume of UHPC Used in China

Based on the data collected via questionnaire forms received from 40 major UHPC related enterprises in China, total 146,500m3of UHPC were used for various projects and products in January ~ December, 2023, and about 180,000 metric tons of UHPC premix produced. Since 2019, thegrowth of annually used UHPC volume in China is shown in the figure below.

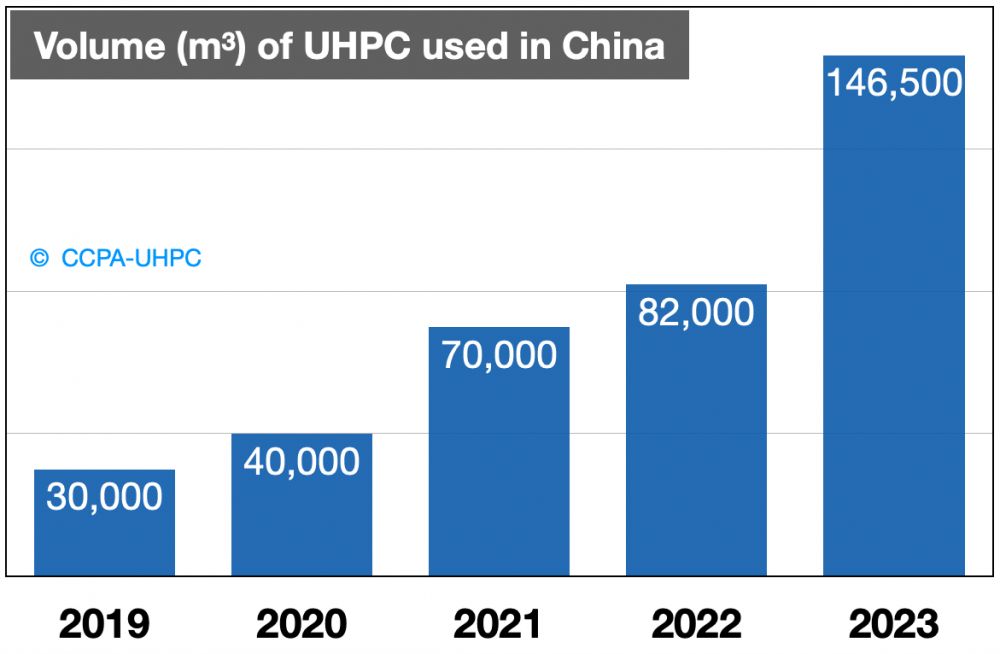

Volume Share of UHPC Applications

The volume share of UHPC used in 2023 is shown in the figure below.

·39% UHPC applied to bridges, in which

Þ17% UHPC used for steel-UHPC composite decks, total completed deck area of more than 349,000m2

Þ14% used for structural connections of precast concrete elements (wet joints), and

Þ8% used for prefabricated components (girders, deck slabs, etc.)

·25% UHPC applied to wind turbine towers and a floating structure

·17% UHPC applied to municipal, power supply & hydraulic engineering

·12% UHPC for buildings, in which

Þ4% UHPC used for prefabricated components (beam, column, staircase, etc.)

Þ8% used for curtain wall and façade, total completed wall area exceeds 368,000m2

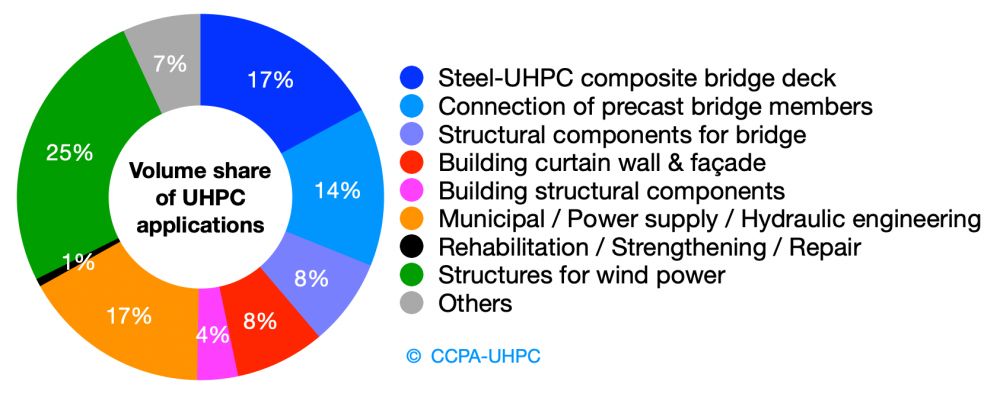

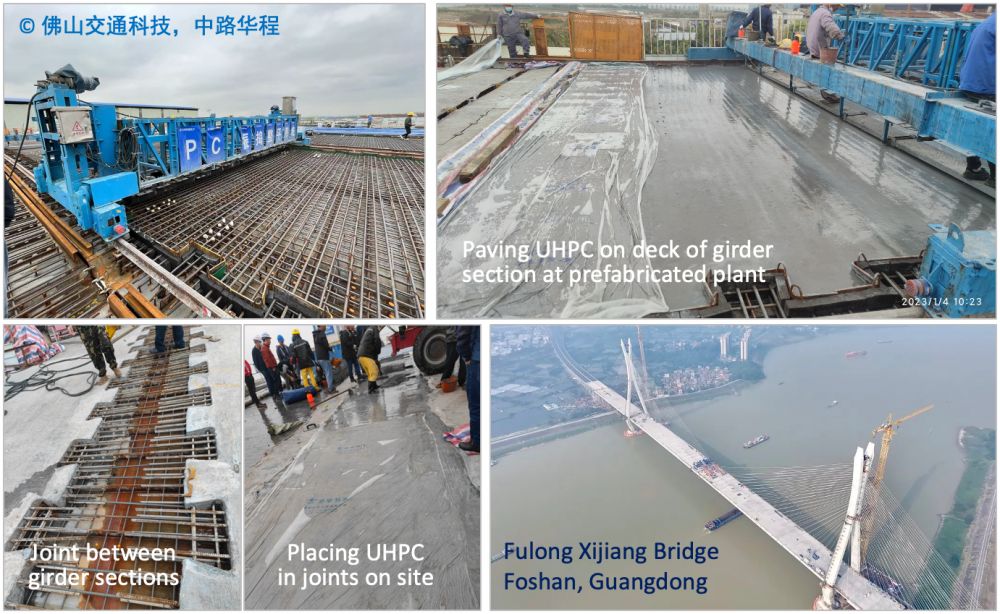

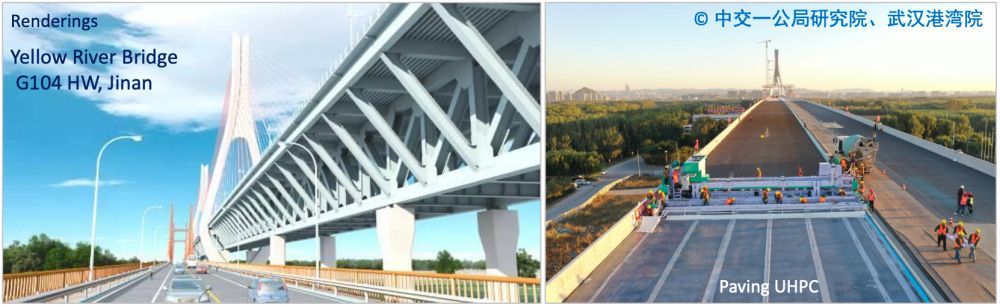

Sustainable Application: steel-UHPC composite deck for bridges

Steel-UHPC composite deck for new bridges and for bridge rehabilitation is well accepted and growing UHPC application in China. The total area of such bridge deck constructed in each year, as well as some bridges built in 2023, are shown in following figure & pictures.

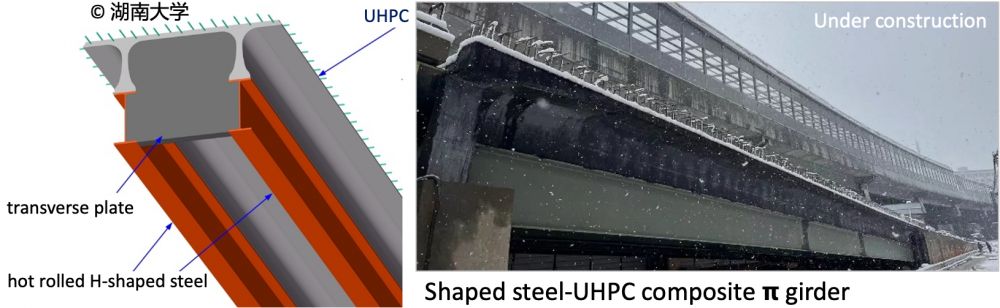

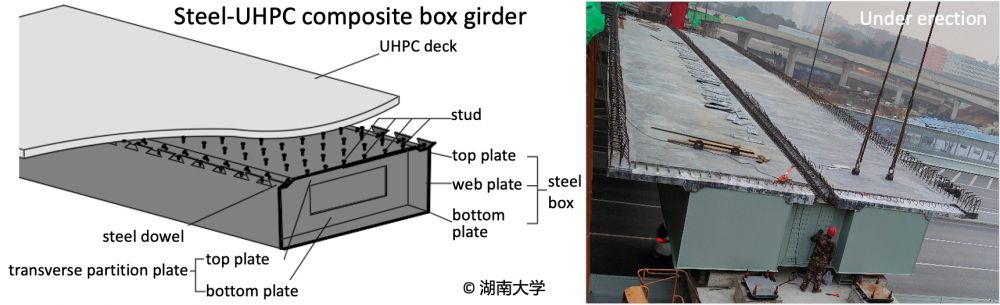

Innovated Structures: new steel-UHPC composite girders

The UHPC bridge team, led by Prof. Xudong SHAO, of Hunan University has developed two new steel-UHPC bridge girders, i.e. Shaped Steel-UHPC Composite?Girder (UHPC?girder with hot rolled H-shaped steel section) and Steel-UHPC Composite Box Girder (steel box with UHPC deck). These two new structures were applied to a viaduct project in Changsha of Hunan Province, as shown in the figures below.

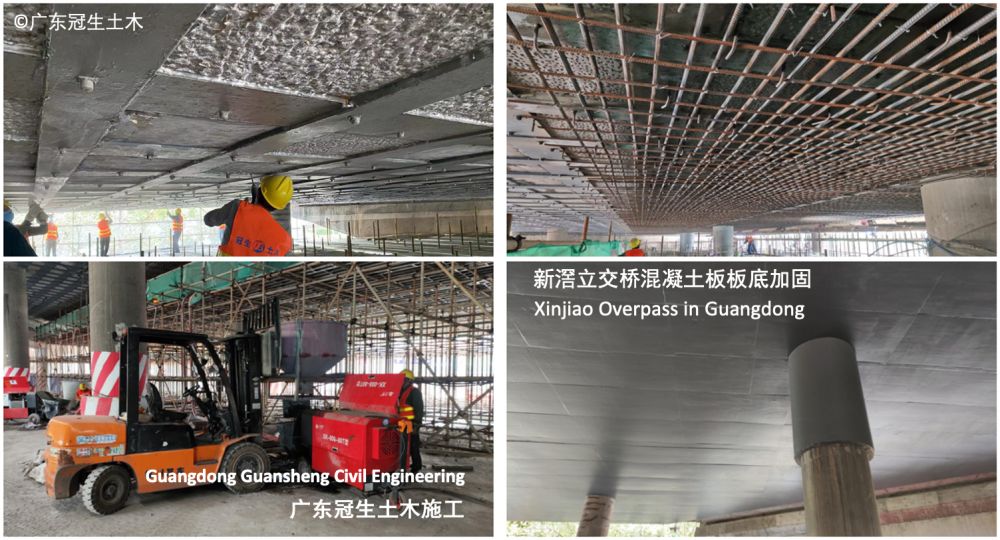

Renovative Solutions: structure repair and strengthening

So far, UHPC applied to structure repair, strengthening or rehabilitation takes small share in volume, but a large potential ahead in China. To execute bridge repair or strengthening with minimal traffic disruptions on heavy traffic roads, the following cases completed in 2023 could be good references.

Xinjiao overpass on Huanan Expressway Phase I in Guangdong was seriously damaged. Its reinforced concrete special-shaped slab continuous structure was strengthened from slab bottom side, see pictures below, executed by Guangdong Guansheng Civil Engineering. During strengthening execution, the overpass kept open, but each time two lanes were temparily restricted, specially for heavy trucks, when underneath the lanes UHPC was placing and in setting period (in 3 days).

In order to achieve longer service life, UHPC is getting popular in China for installing new bridge expansion joint, as well as for fast repairing the damaged joint. In 2023, Guangzhou Pengyue had quickly repaired the bridge expansion joints of several bridges in Guangdong Province with their fast-hardening UHPC, which allows to open traffic in 3 hours from UHPC paved, therefore, the repair execution could be easily completed within the window time of 7 hours (close traffic from 11pm to 6am).

Breakthrough: UHPC for wind turbine towers

First UHPC&steel hybrid wind turbine tower with turbine hub center height 180m (UHPC section high 157.4 m and upper section made of steel) was erected in Oct. 2023 for Jushi Wind Power Project, Lianshui, Jiangsu. To the end of December 2023, 50 UHPC&steel hybrid wind turbine towers were erected in China, consuming 35,193m3UHPC. The UHPC segments were prefabricated by Shanghai FL Renewables and Suzhou Concrete Cement Products Research Institute. Thanks to the excellent ductility of UHPC, the reliability and safety of UHPC&steel hybrid tower structures is expected to be effectively enhanced in comparison with steel towers or concrete&steel hybrid towers. UHPC&steel hybrid structures could be reliable and cost-efficient solution for constructing taller wind turbine tower, e.g. hub center height 200m ~ 300m.

Innovative Activities: UHPC for building curtain wall or façade

The building curtain walls or façades built with prefabricated UHPC components have excellent properties, such as durable, light but strong, high seismic & impact resistance, good stain resistance, etc. Those advantages are getting known more and more among architects, thus UHPC applications to curtain walls or façades are increasing in recent years in China. According to incomplete statistics, in 2023, more than 368,000 m2, the total area of UHPC curtain wall and façade components, prefabricated in China. Some building examples are shown below.

Three Island City Meeting Room is located in Zhuhai at the geometric center of Hong Kong, Macao and Zhuhai, exposed to marine environment. Its curtain walls and column profiles are assembled with plane & curved, 20mm thick, precast white UHPC panels, total area of 3,300m2, prefabricated by Shanghai Tongchuang. UHPC is chosen here for high resistance to sea salt spray and weathering, as well as for protecting the main structures from aggressive marine environment.

Teacher Training Center, 9# Building of Yancheng Experimental Middle School of East China Normal University, is a show case for passive, high energy efficient building. Light-weight, white UHPC components, prefabricated and installed by Zhejiang Possible, are widely used in this show case building, including façade, moving sun screen, duct profiling, etc., see pictures above.

Shanghai South Bund Sanitation Building encompasses a construction garbage sorting center and an automobile repair shop. Its curtain walls consist of large curved, self-supporting UHPC panels. The panels are only reinforced with stainless-steel fiber, i.e. no steel bar used and installed without steel frame. The design of UHPC panels is optimized by Shanghai C&E Engineering, and experimentally tested and verified. The installation of UHPC components without steel frame but only stainless-steel fasteners means that there is no exposed steel structure - maintenance free and long service life secured.

The façade of SRIBS new building consists of precast UHPC 3D wall panel (integrated insulation, decoration, ducts, etc.), prefabricated by Zhejiang Possible. As a new design, the real panels & installation/anchorage design were tested for seismic resistance. After experienced the simulated 9.6 magnitude earthquake (see the picturesbelow), only slight cracks appeared at the hanging points, no other damage occurred on the panels.

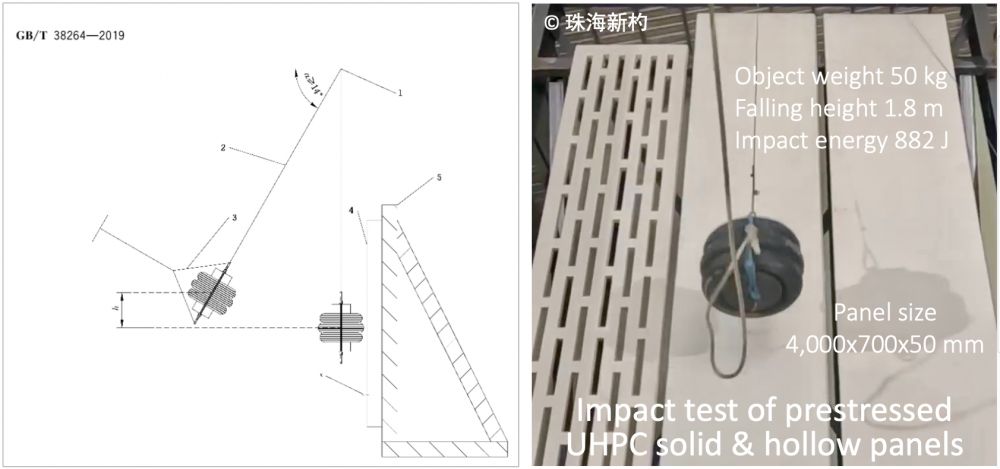

Zhuahai Xingshao developed large size, heavy-duty, prestressed UHPC solid and hollow curtain wall panels. A series of impact resistance test, conducted according to China national standards GB/T 38264-2019, show that no cracking or other damage occurred on the panels (size 4000x700x50mm, solid & hollow) after being subjected to the impact of 50kg object with 882J energy (see figuresabove). These prestressed UHPC panels are well satisfied the impact resistance requirements of level 3 (the highest level), capable of resisting a load of more than 7.5kPa and meet the mechanical requirements of various curtain wall (without steel frame), including high-rise and super high-rise buildings.

Creative Products of UHPC

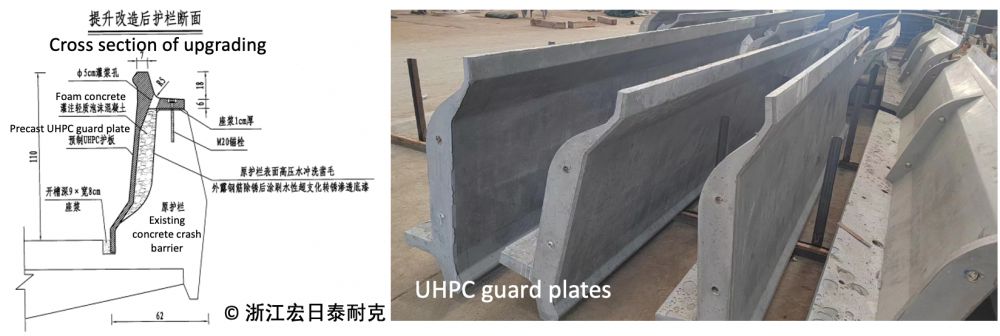

In China, the standard ‘Code for the Design of Highway Traffic Safety Facilities’ (JTG D81-2017) was revised in 2017, and the stipulated levels of highway crash barriers for protecting vehicles had been increased. A large number of existing highway concrete crash barriers need to be upgraded to meet the new requirements. Zhejiang Hongri Tenacal and Ningbo Traffic Design & Research Institute have jointly developed a UHPC guard plate (see figures below), which can be installed on the existing concrete crash barriers for enhancing the protection capabilities. The full series, full-scale crash tests of various vehicle types proved that the concrete crash barriers upgraded with this UHPC guard plates can well meet the protection requirements of standard JTG D81-2017. In 2023, this upgrading solution has been applied to a connection line of Hangzhou Bay Bridge in Ningbo.

Huaxin Chaokelong has developed thin UHPC roof tiles and wall panels products, which are not only light, strong but also durable – high resistance to weathering and chemical attack, thus are good substitutes of GRP tiles and panels for industrial buildings. These UHPC tiles and panels have been extensively applied to the newly constructed plant, Yangxin Manufactured Sand Plant of Huaxin, total area of 347,000m2used, see pictures above.

Guangzhou Pengyue has manufactured the vertical UHPC modules for flower planting, solar panels installation, and as decorative fence, see pictures below.

Jianhua Building Materials has fabricated UHPC tree enclosure grates (see pictures below), a low-carbon replacement of traditional tree enclosure grates made of cast iron.