Precast U-shaped Concrete Composite Bent Cap Used in Heavy Load Traffic for the First Time in China

On November 30th, the first trusses of precast U-shaped concrete composite bent cap were installed in the Pudong Section (Main Line 1) Project of the Yangtze River Channel designed by STEC Shanghai Urban Construction Design & Research Institute and constructed by STEC Shanghai Urban Construction Municipal Engineering (Group) Co., Ltd., marking a new stage of the bridge substructure of the project.

On November 30th, the first trusses of precast U-shaped concrete composite bent cap were installed in the Pudong Section (Main Line 1) Project of the Yangtze River Channel designed by STEC Shanghai Urban Construction Design & Research Institute and constructed by STEC Shanghai Urban Construction Municipal Engineering (Group) Co., Ltd., marking a new stage of the bridge substructure of the project. During the construction, STEC innovatively realized the first application of precast U-shaped concrete composite bent cap in heavy load traffic in China, which greatly enhanced the construction efficiency and strongly guaranteed the high quality and safety of the project.

The Pudong Section Project is connected to the national highway G1503 main line, the total length of about 18 kilometers. Among them, the core part of the project constructed by STEC Shanghai Urban Construction Municipal Engineering (Group) Co., Ltd. is located in the westernmost part of the Pudong section where it meets the Yuejiang section, east to the west part of the Gaoxin River, with a total length of 2.56km.

Fast and Efficient Engineering Through Lightweighting of Components

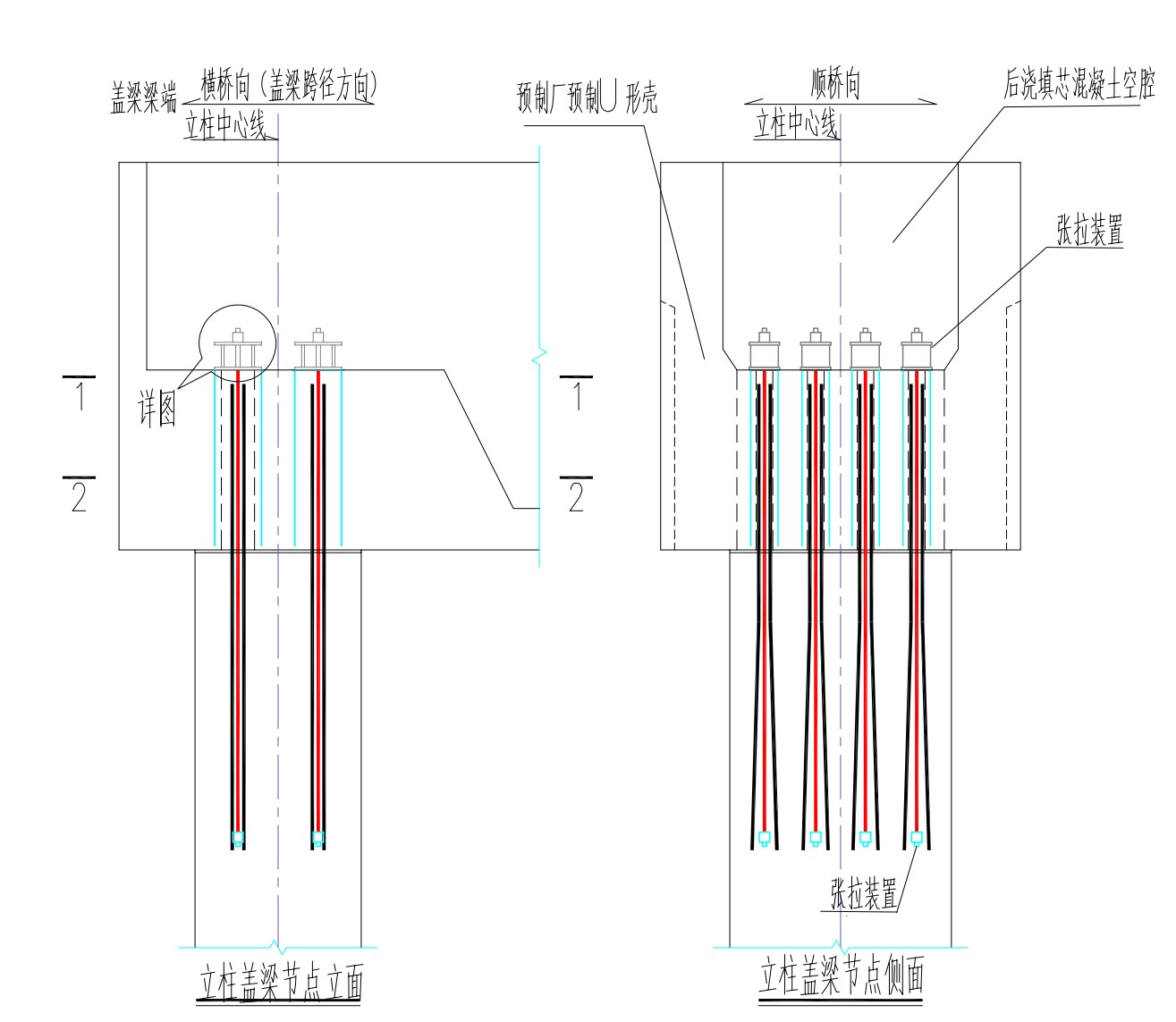

The core part of the Pudong section (main line 1) of the channel crosses the S20 and other existing roads, which are heavily trafficked and cannot be closed for long periods. If conventional methods such as cast-in-place integral bent caps, segmented bent caps, or precast integral bent caps were used, they would not only be heavy, difficult to transport, and inefficient, but also require long periods of road occupation for construction. After a specialized study, the STEC Shanghai Urban Construction Design & Research Institute proposed a precast U-shaped concrete composite bent cap construction plan, which involves precast U-shaped molds, transporting them to the site, assembling, and then casting core concrete to form a prestressed composite load-bearing structure.

The lifted U-shaped concrete composite bent cap was 25.9m long, 2.6m wide and 2.8m high. The precast U-shaped concrete shell weighs 220t, and after filling the concrete on site, it weighs 487t. During the on-site assembly, only less than half of the total weight of the precast molds needs to be hoisted, greatly reducing the load pressure on the lifting equipment and minimizing lifting risks. Additionally, the on-site pouring process does not require formwork or rebar binding, further improving construction efficiency. Moreover, the lifting operation only temporarily occupies two lanes of the outer four-lane one-way road. By using a half or partial lane construction method, the lifting of a single U-shaped composite bent cap can be completed within one hour, maximizing the road capacity during construction.

Construction Refinement Brings Safety and Stability

In order to ensure the safety and stability of the structure of U-shaped composite bent cap, during the prestressing tensioning operation, based on the structural and construction characteristics of the bent cap, the project team designed a reliable, safe and durable vertical prestressing structure for the column bent cap, which means that the U-shaped composite bent cap and columns were connected with reinforcement bars before pouring the concrete in the shells, and the prestressing tensioning and anchoring were completed. Traditionally, after the erection of the superstructure, only the second prestressing tensioning is performed on the traditional cover girder, while the use of this prestressing structure can effectively increase the integrality of the substructure and improve the shear strength. At the same time, the stressing system and reinforcement design are more reasonable, and the secondary casting is more convenient, which can reserve more working space.

Greening of construction brings low carbon and environmental protection

In the production of precast components, STEC Shanghai Urban Construction Municipal Engineering (Group) Co., Ltd. adopts a standardized and modular design concept, with each part prefabricated as flat panels, effectively reducing the amount of formwork used. Additionally, the prestressed concrete structure offers better durability. Compared to traditional steel bent caps, the new technology and processes not only save resources during construction and reduce later maintenance costs, but also minimize the impact of operation and maintenance on the traffic environment, bringing significant socio-economic benefits.

The Pudong section of the Yangtze River Channel (Yuejiang Section—Wuzhou Avenue), as a key project in Shanghai, is the final segment of the national highway G1503 's independent loop. Once completed, this project will integrate with the Tongjiang–Sanya Highway, the Southeast Jiaohuan Tunnel, the Pudong Jiaohuan Tunnel, and others, transforming the 'C'-shaped into an 'O'-shaped. This will thoroughly eliminate the functional gaps and traffic bottlenecks in Shanghai's regional highway network and mark a significant milestone in completing the construction of the national expressway network within Shanghai.