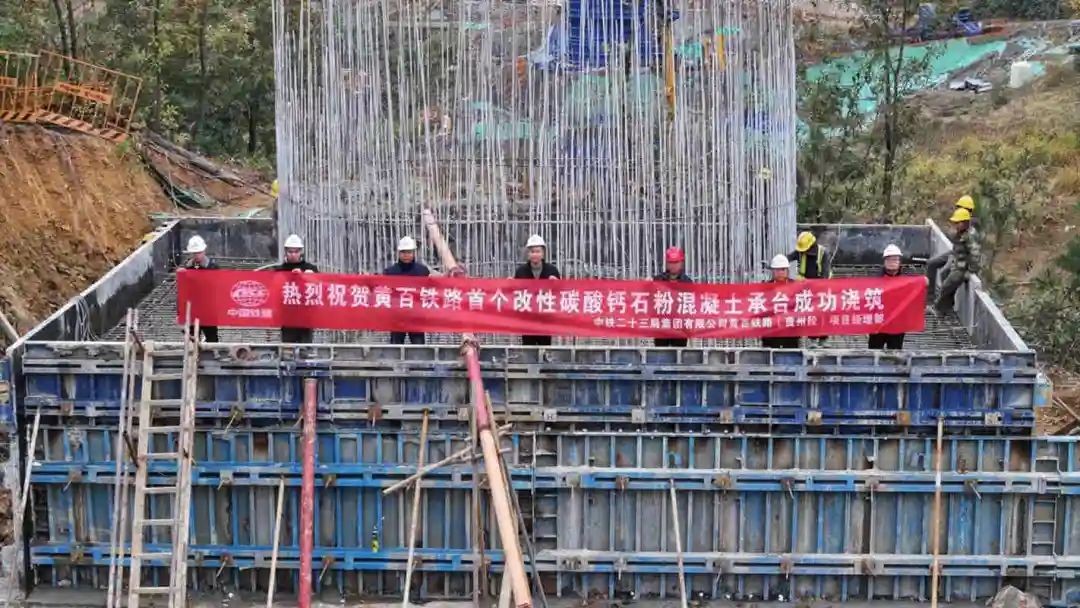

The Modified Calcium Carbonate Stone Powder Concrete Has Been Successfully Applied in the Casting of Structural Elements in Guizhou Section of Huangtong-Baise Railway

The modified calcium carbonate stone powder concrete has been successfully applied in the casting of structural elements such as bridges and tunnels, breaking the traditional practice of using fly ash as a concrete admixture.

Recently, a major technological breakthrough was achieved in the concrete construction of the first three sections of the Guizhou section of Huangtong-Baise Railway. The modified calcium carbonate stone powder concrete has been successfully applied in the casting of structural elements such as bridges and tunnels, breaking the traditional practice of using fly ash as a concrete admixture.

The first modified calcium carbonate stone powder concrete pile cap of Huangtong-Baise Railway has been successfully poured. (Photo by Li Ke)

"Modified calcium carbonate stone powder has stable performance, which can be sourced locally, and ensures both production capacity and quality. It represents a concrete measure for green construction," said Dr. Lu Qingyuan, head of the Doctoral Innovation Studio at the Huangtong-Baise Railway Project Department of China Railway 23rd Bureau Group Co., Ltd.

Modified calcium carbonate stone powder concrete is a new type of building material that uses calcium carbonate stone powder as its main raw material. Through a specialized modification process, it achieves excellent physical properties and chemical stability. Compared to traditional fly ash concrete, modified calcium carbonate stone powder concrete offers higher strength, better impermeability, and improved frost resistance. Additionally, it reduces costs and minimizes environmental pollution.

The Huangtong-Baise Railway connects to the Shanghai-Kunming Railway in the north and the Nanning-Kunming Railway in the south. Designed as a national Class I electrified railway with a speed of 160 km/h, the Guizhou section spans approximately 173 kilometers, with a bridge-to-tunnel ratio as high as 81.6%. Addressing challenges such as the high proportion of bridges and tunnels, the large demand for concrete, difficulties in controlling fly ash quality, and long transportation distances, the functional Party branch of the Guizhou section of the Huangtong-Baise Railway collaborated with the project management team of China Railway 23rd Bureau to conduct technical research on concrete raw materials.

To ensure the successful application of modified calcium carbonate stone powder concrete in practical casting, the innovation studio team conducted in-depth research and experiments. These studies ranged from the interaction mechanisms of the microchemical components of modified calcium carbonate stone powder concrete to the performance of macro concrete mixtures, the strength of standard concrete specimens, and durability indicators. Supported by extensive experimental data, the team recently completed the application of modified calcium carbonate stone powder concrete in the casting of bridges and tunnels. Testing of synchronized concrete curing specimens showed that the concrete's compressive strength, impermeability, and other technical indicators met the design and regulatory requirements, achieving excellent results.

In recent years, fly ash, widely used as the second-largest admixture in concrete, has faced a significant decline in production and quality due to environmental policies and resource depletion. This has made it increasingly urgent to identify a material that can replace fly ash as the second-largest admixture in cement concrete. "It took more than 180 days from research and experimental validation to practical casting application," said Lu Qingyuan.

"The successful application of modified calcium carbonate stone powder concrete has not only solved the challenges of unstable supply and quality of fly ash during construction but also allowed us to utilize tunnel debris, turning waste into a valuable resource and reducing concrete construction costs," said Li Qingyuan, the material manager of the project department.

According to Zhang Bin, Deputy Commander of the Ziyun Command Center of the Shanghai-Kunming Railway Passenger Line Guizhou Co., Ltd., as the promotion of ecological civilization and green low-carbon development intensifies, the requirements for controlling fly ash resources have become increasingly stringent. Using modified calcium carbonate stone powder as an admixture in concrete effectively addresses the shortage of admixtures. At the same time, it reduces costs, minimizes environmental pollution, and represents an innovative breakthrough in the field of building materials with broad development prospects.